We offer complete solutions for EBIC imaging and analysis. We can provide a custom package that includes everything you need to conduct EBIC measurements on your SEM.

Hardware

Our scan controller, the Mighty EBIC 2.0, has been designed specifically for measuring very low EBIC signals.

Femtoamp sensitivity at highest gain setting (0.76 fA resolution)

Wide dynamic range at each gain setting 108 dB

8 imaging inputs compatible with all +-10V signals, SE, BSE, CL, lock-in amplifiers, etc...

Sample biasing and transport measurements in-situ.

Software

Our imaging and analysis suite is designed to be flexible and can handle many different types of signal inputs.

Channel mixing, of input channels

Extract diffusion lengths with line profile tool and arbitrary user defined fit functions.

Software Design Kit (SDK), is installed on the host pc included with every scan controller.

Unlimited software client installations

Numpy and Scipy, are built-in giving you advanced numerical and scientific processing power.

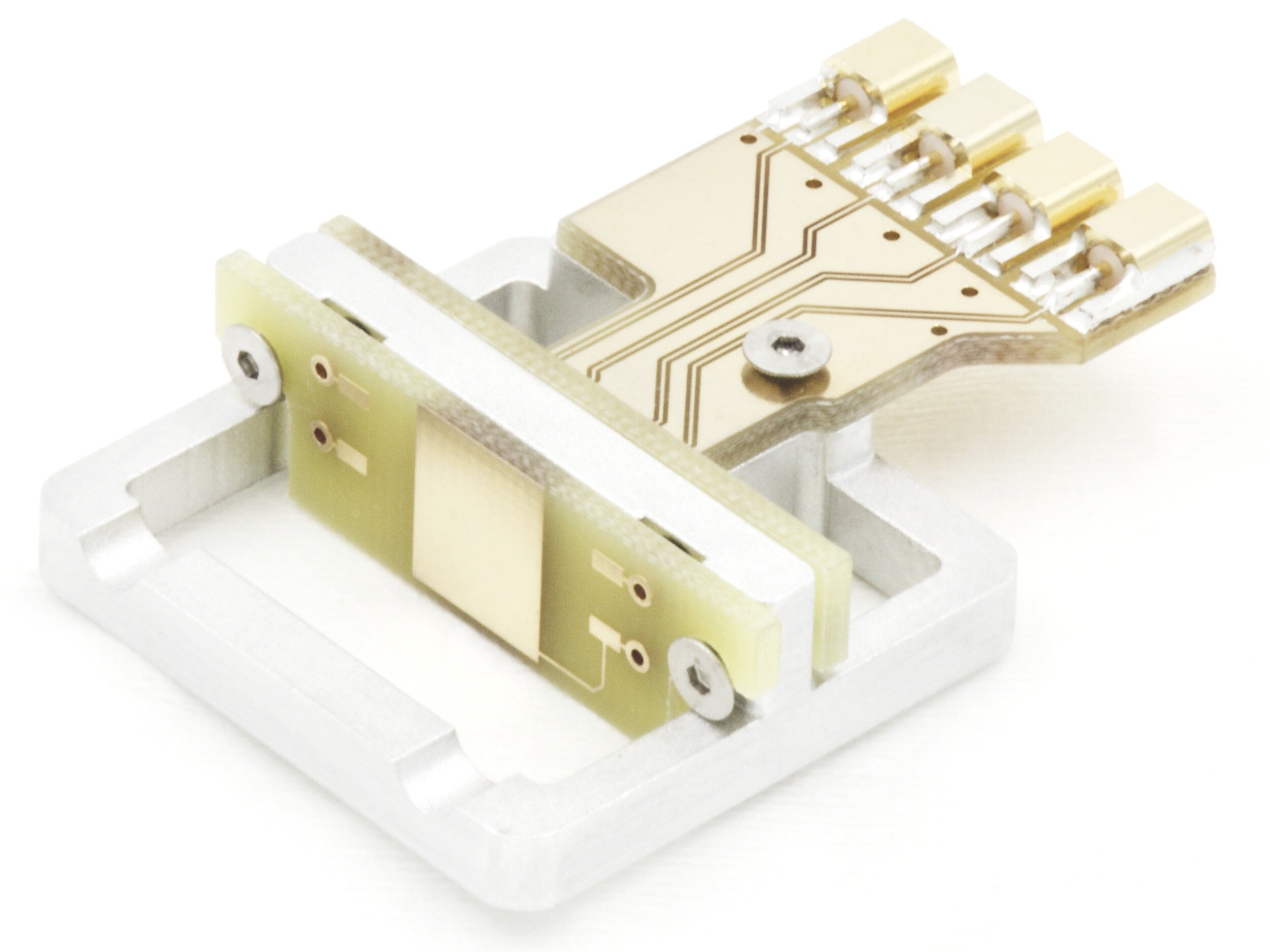

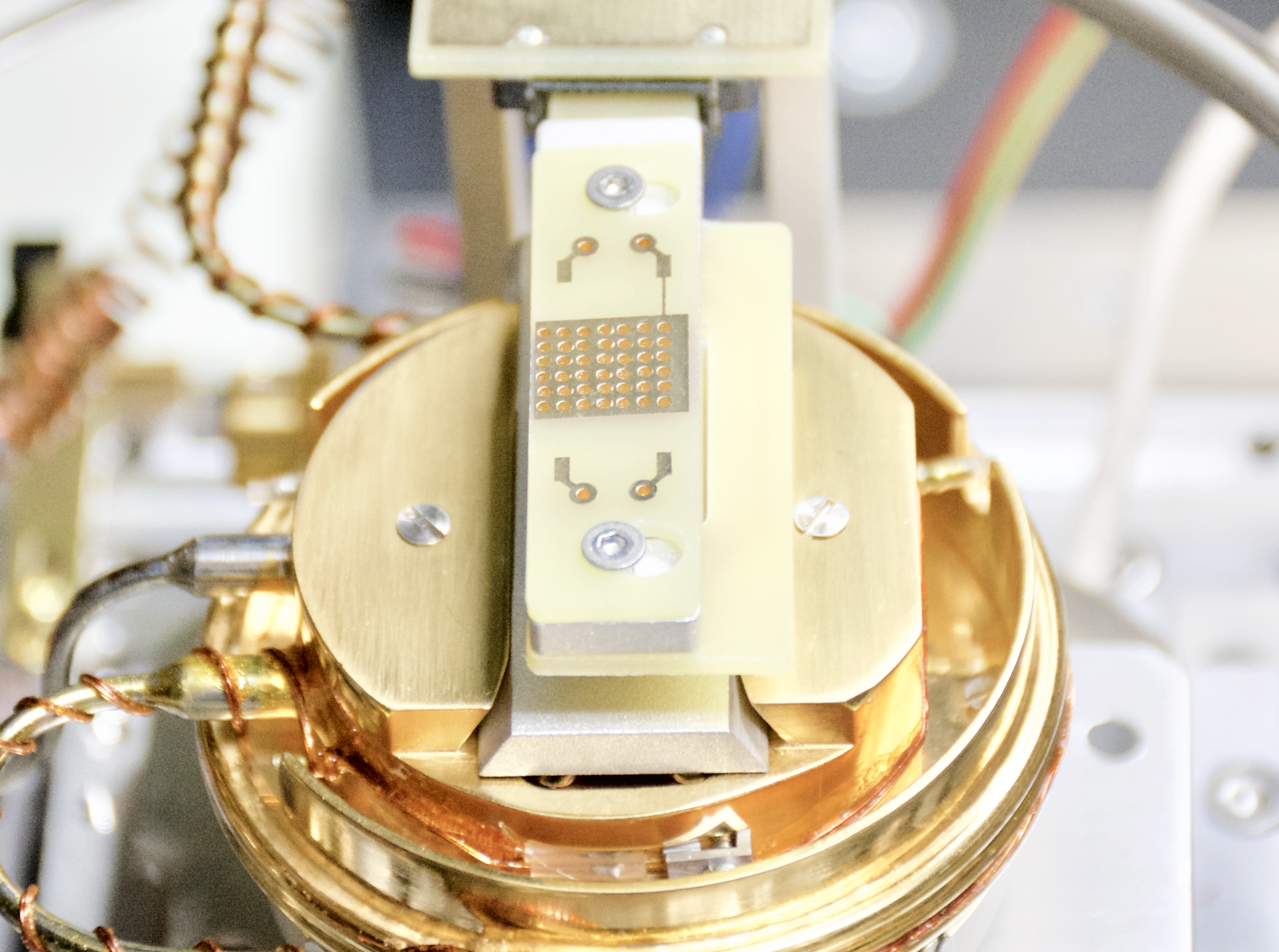

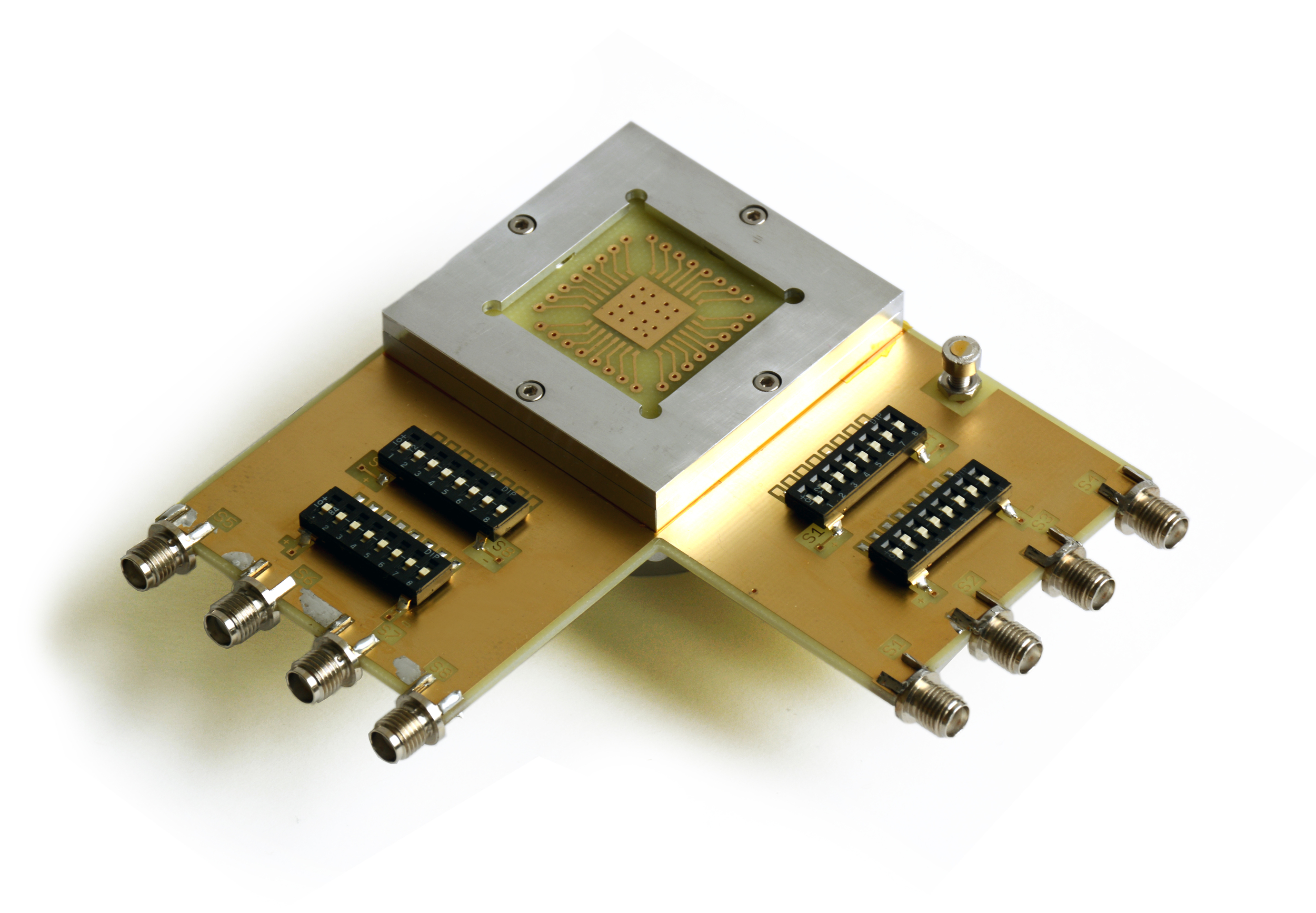

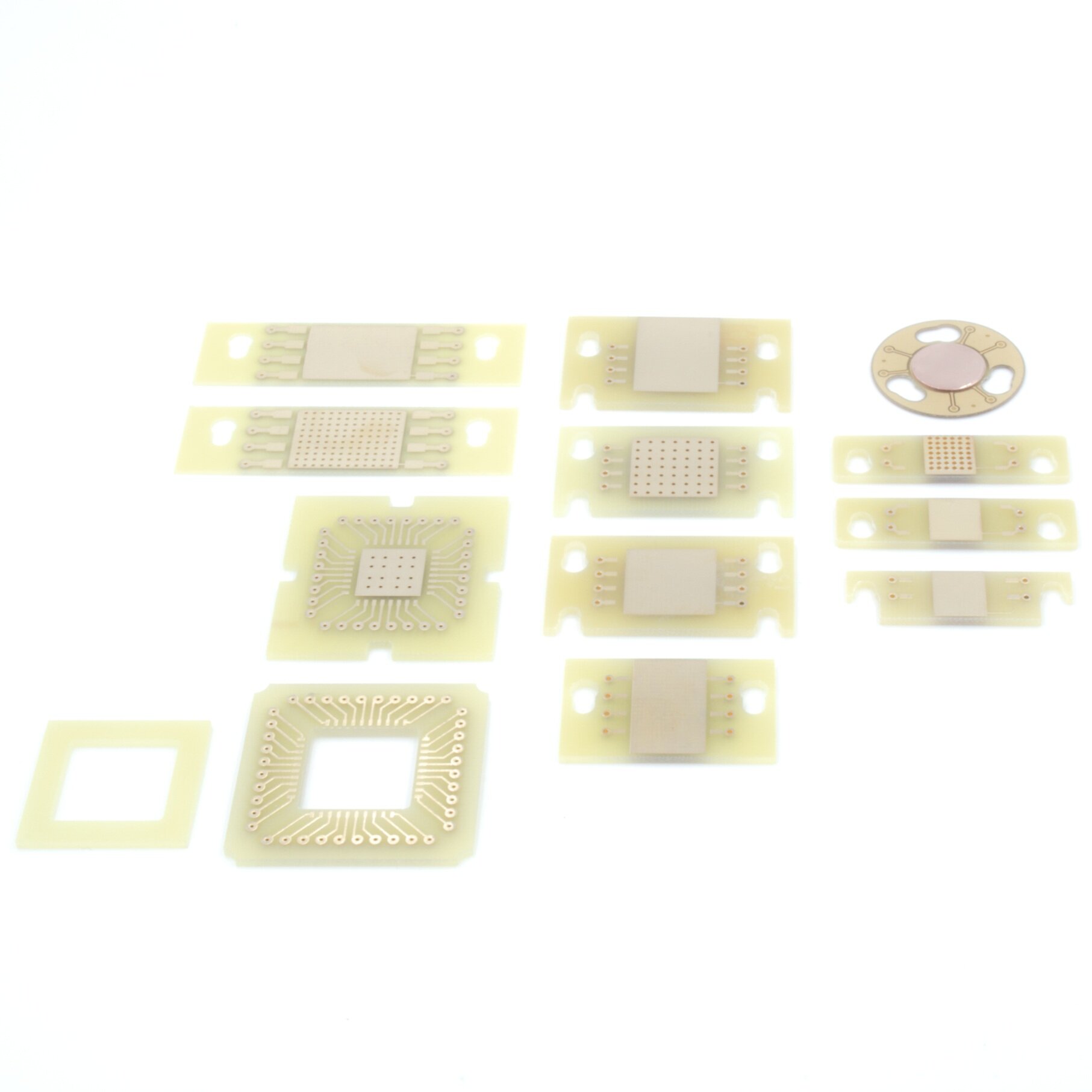

We have designed many different types of sample holders. Our general purpose sample holder enables several devices to be tested on one chip carrier.

Multiple contacts of the chip carrier that can be programed with a DIP switch

Faraday cup that is adjustable to the sample height

Coaxial connectors, for added shielding

Adaptable to almost any SEM stage

We can design a custom chip carrier and sample holder for your specific application.

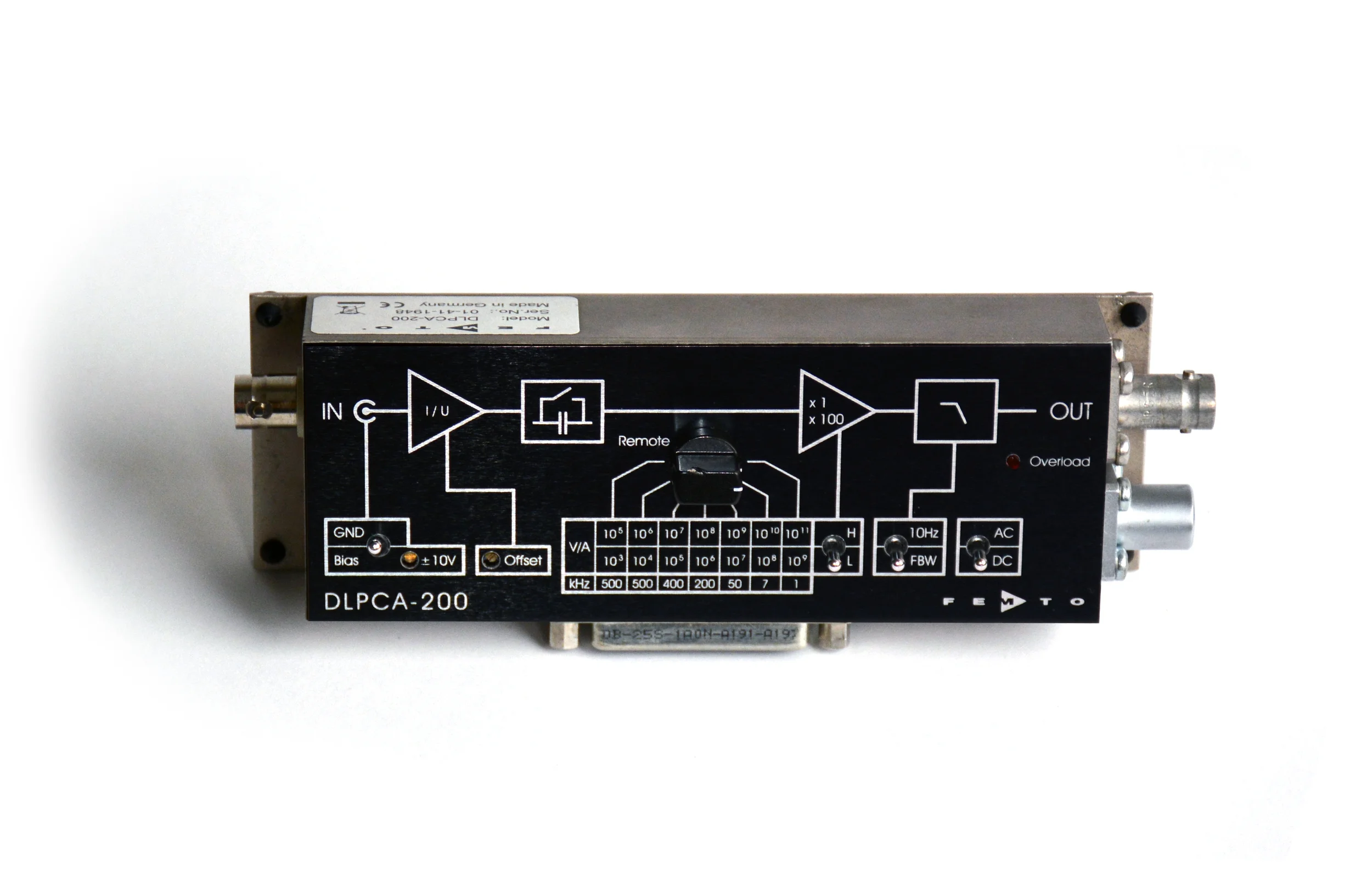

FEMTO makes the best pre-amplifier for EBIC measurements. Combined with our scan controller you can make quantitative current measurements with 0.76fA resolution.

Transimpedance gain from 1E3 to 1E11 V/A

Input noise down to 4.3 fA/√Hz

AC and DC coupling

Bandwidth up to 500 kHz

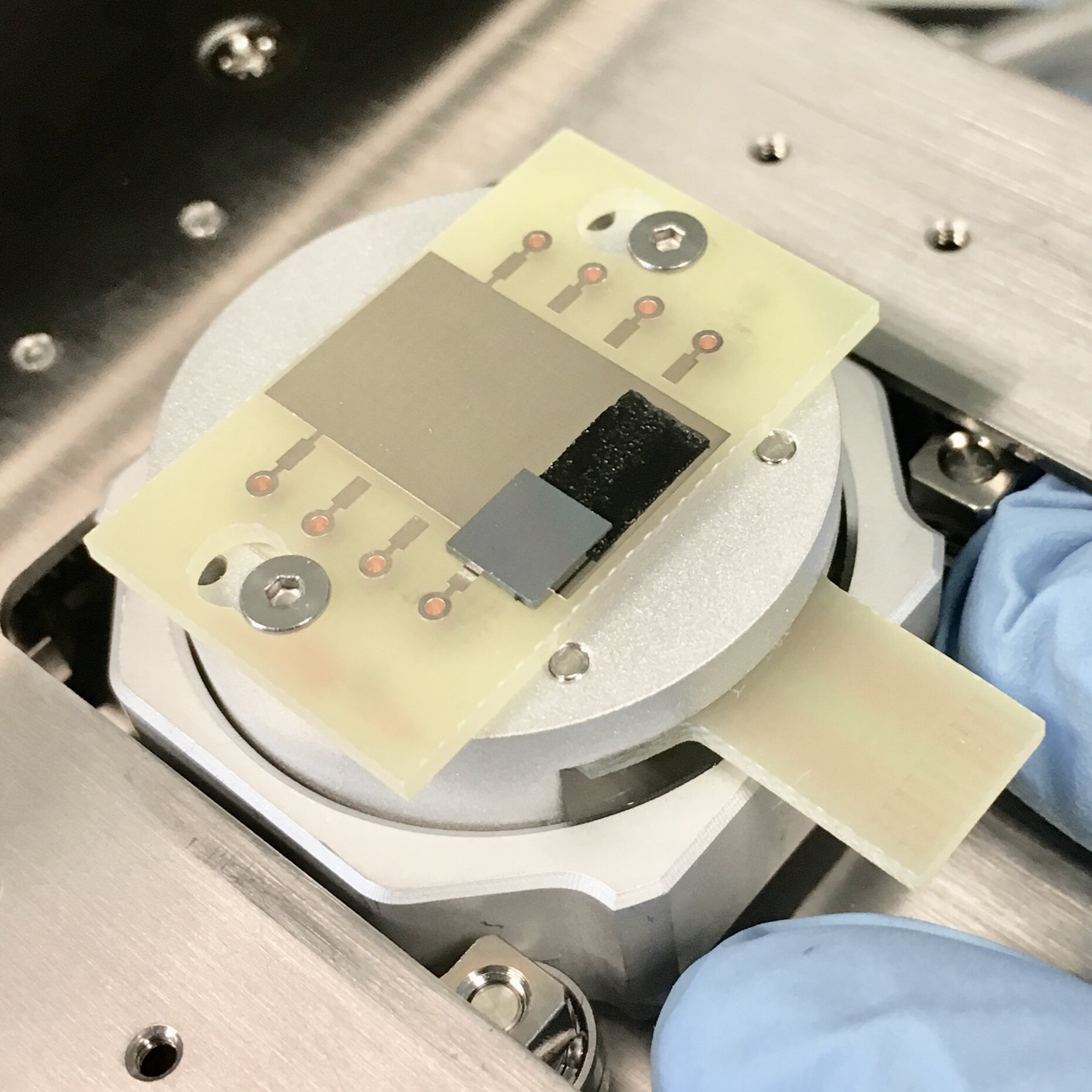

Manual wire bonding using micropositioners and reversible tweezers to position bond wire dipped in conductive epoxy.

Fast and simple sample contacting with out expensive wire bonder and potential damage to sample.

Gentle processing, conductive epoxy can be cured at ambient conditions.

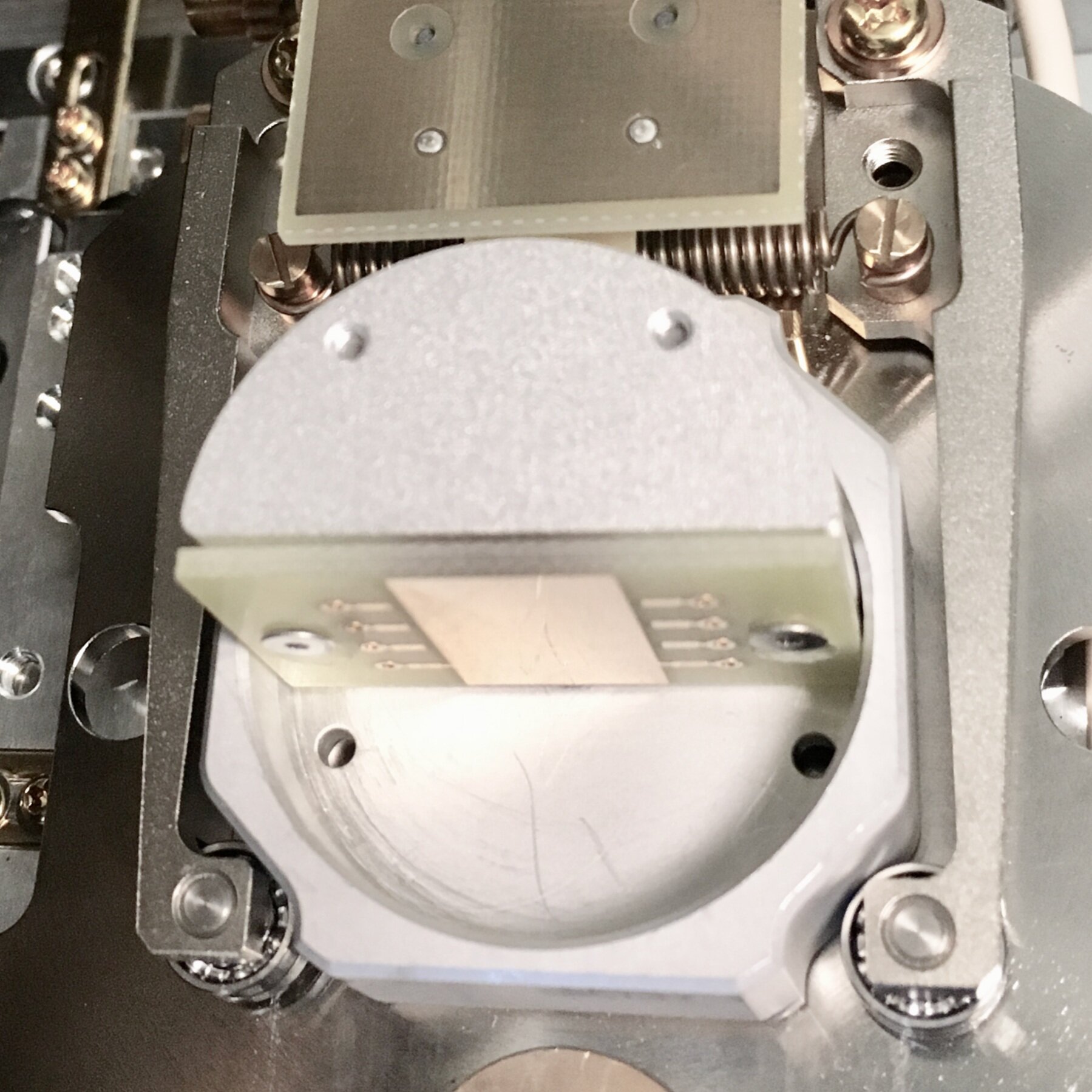

We can make a custom feedthrough with SMA connectors on an available port.

Coaxial SMA connectors provide shielding inside the chamber

The number of SMA connectors is only limited by the size of the port.